From Waste to Valuable Materials and Energy

A new recycling technology for keeping the environment clean and healthy for generations -made in Germany-

Waste and its proper disposal is a global problem. In many countries garbage dumps, containing both household and industrial waste, are polluting the landscape because there are no other disposal solutions available. As a result, the seas are polluted and ground water contaminated, which endangers people’s health around the globe. Incineration isn’t the solution because of its negative impact on air, soil and water. For example, dangerous waste materials, such as dioxin, furan, CO2, fine dust or heavy metals, are generated during incineration. These negative by-products can only be reduced through extensive investments in costly exhaust gas filter systems.

On the other hand – in times of scarce and expensive ressources – efficient ways of recycling without incineration need to be deployed in order to produce valuable secondary materials and energy. Despite these basic insights in many countries worldwide incineration with and without energy production and landfills are still reality with all aforementioned negative impacts.

Recycling rates in OECD variegate from country to country depending on type of material used. Germany e.g., with annual 160 kg /capita world champion in waste production, is recycling plastic waste only up to 30%, the rest of 550.000 t per year is being incinerated or exported.

About 75 % of 3.5 million old rubber tyres a year in Europe, are incinerated in cement kilns or granulated for public work or other purposes with limited or decreasing demand. EU rules force tyre producers instead of incineration to recycling and other methods to convert tyres to valuable secondary products.

The need to establish sustainable solutions to solve waste problems worldwide has motivated MONOPTEROS to support innovative activities and young companies in establishing efficient and environment proctecting waste management technologies.

One of these companies supported by MONOPTEROS is Global Enertech, offering a future-oriented, efficient, waste disposal system – GLOBATEC, made in Germany – that keeps the environment clean and healthy for coming generations.

As an alternative to conventional waste incineration GlobaTec is economical, pollutant-free, flexible and scalable.

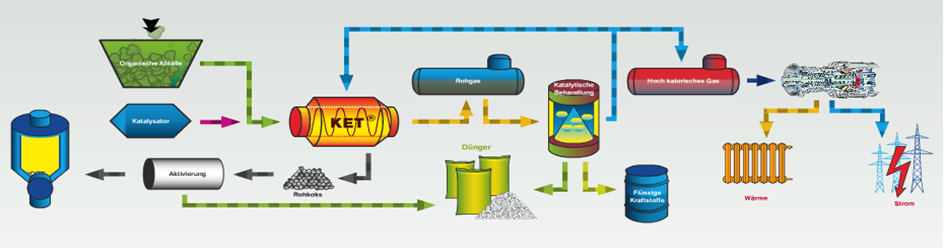

The GlobaTec method is a patented process for the thermocatalytic degassing of industrial and household waste by indirect heating to approx. 550 ° C with the addition of catalysts. In this manner, industry and household waste not normally recyclable can be processed. Waste materials are converted into high-caloric gas, raw coke and high-quality, clean crude oil. As needed, the coke can be activated and crude oil converted into liquid fuels in a subsequent step. Approximately 20% of the recovered gas is used for the operation of the plant, thus its energy supply is covered.

The activated coke is, among other things, usable as filter material for the treatment of waste water or for the cleaning of smoke or dirty gas.

In addition to gas, coke and water treatment material, other end products (for example, fertilizers, bitumen, etc.) are produced, depending on the waste material supplied. Approximately 80 % of the catalyst materials are recycled in the process.

An economically viable operation is attained from processing a minimum of 0.5 t/h of waste material (approximately 12 t /d.) The composition and the amounts of gas, oil, activated coke, as well as fertilizers, depend on the input materials.

The following applications are, among other things, possible:

- Recycling of used tires

- Recycling of pre-sorted household and industrial waste

- Recycling of residues from electronics and cable recycling

- Recycling of waste from mills (for example, hulls of oats, spelt, buckwheat, etc.) or similar biowaste

- Recycling of polystyrene (packaging and construction polystyrene) – in development

- Recycling of glass fiber material – in development

Global EnerTec AG, founded 2013, operates a first plant for testing and demonstration in Guben, German. This plant has been used in permanent operation with a wide variety of waste input materials. The GlobaTec process is patented and the system is certified by one of the leading safety inspection companies of the world, based in Germany. First commercially operated systems are under construction in Germany, Africa and Europe.

For any further information or request to site inspection of the first plant in operation pls contact:

CONTACT

|

|

|